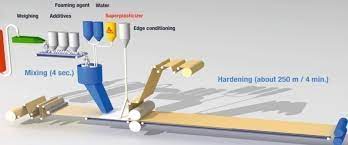

ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics. To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock. Next the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of recycled paper on a long board machine.

At some gypsum plants, drying, grinding, and calcining are performed in heated impact mills. In these mills hot gas contacts gypsum as it is ground. The gas dries and calcines the ore and then conveys the stucco to a product cyclone for collection.

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO. 2H2O. It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk chalk.

Gypsum board paper (drywall paper) is categorized into regular paper, water proof paper, fire proof paper, and sound proof paper. Gypsum board paper is used to covering paper for gypsum board.